My modified scintillation detector.

I took apart a commercial Sodium Iodide (NaI(Tl) Scionix-Holland) detector from an Exploranium GR-135 and reworked the whole Dynode Voltage divider circuit. In addition, I installed a bulkhead BNC connector on the cap of the housing - the original detector just had cables coming from a rubber grommet on the side of the cylinder.

These are older but quite nice, all-around, spectroscopy-grade detectors that can be found used as part of surplus sales and are not outrageously expensive as most such detectors - mine came from a "Border Patrol contract" GR-135 unit.

I was lucky to find a unit with ~7.5% resolution at 662 keV - while this is typical of these detectors, if the device was abused, crystal was cracked or moisture got inside, performance will greatly deteriorate, or it could be rendered completely useless for Spectroscopy.

The scintillation detectors are very expensive and fragile devices and should be protected at all times (!!!). The housing must be sealed air-tight as ambient moisture will destroy the crystal, any ambient daylight will destroy the PMT when bias voltage is applied! Tiny light leaks will spoil the measurements, mechanical shock (even a simple drop) can damage both, the crystal and break the glass-envelope PMT (which is a vacuum tube in an essence), bias over-voltage will shorten the PMT's life, etc.

I am storing my detectors in a well-padded Pelican case with some Silicagel bags to absorb moisture.

One should pay attention at the cosmetic condition (as everything is factory sealed anyways) when buying a used and/or untested detector as this usually can show evidence of rough handling. The bottom, aluminum part where the crystal is encapsulated should not have any dings (!) or deep scratches.

Considering how fragile these devices are, the risk of buying a damaged / dropped detector is very real!

The original detector as just removed from a GR-135 unit cannot be used directly with GS-USB-PRO - the Dynode Voltage Divider must be completely reworked.

The role of the PMT voltage-divider is to provide HV for the tube's Cathode-to-Anode bias and gradual voltage to all of the dynodes in-between, as each dynode receives higher voltage than the preceding one, thus progressively increasing the gain with each consecutive dynode stage (Hamamatsu R980 PMT has 10 dynode stages). This process achieves multiplication of the electrons in an "avalanche effect" until all electrons are collected by the anode. The overall multiplication factor follows the level of the High Voltage bias input.

The original divider in 38B57 is a transistorized circuit and has a number of active components - it is designed to work with the firmware in GR-135 where the linearity is compensated for in the software and tailored for a specific energy range. Such divider will provide very poor linearity if used directly, in a conventional way - a "classic" PMT dynode voltage divider is needed.

This is the original circuit on the back of the PMT. Cables are fed thru a sealed rubber grommet on the side. Easiest way to rework the divider is to completely remove the board. As there is no socket for the PMT and the PMT itself is equipped with wire pins which are not suitable for a socket, all 12 pins must be de-soldered from the PCB. The PMT is a glass-envelope vacuum tube and caution must be exercised when de-soldering. If the stainless steel outer housing is not removed (and it is nearly impossible to be removed non-destructively as it is glued extremely well), installing the board onto the PMT leads can be quite difficult but not impossible - it took me about 20 min to re-align the stiff lead wires with the PCB holes. I just didn't want to even try to remove the main detector housing - it is glued and sealed to the crystal housing with a very strong adhesive, and I just didn't like the idea of disturbing the assembly.

Caution! The PMT in 38B57 is glued and sealed directly to to the front of the crystal inside the lower aluminum housing and it can not be replaced if damaged without destroying the crystal. Basically, other than the voltage divider, nothing else in these units is serviceable. It is an all-in-one type design with no separate encapsulation for the crystal.

Alternatively, one can work on and rebuild the voltage divider even without removing the original board - I did it for another detector and it was not difficult at all.

I removed all of the old components and had to figure out way how to apply the new divider circuit using the old PCB, traces and pads.

The board was cleaned from solder and old flux before soldering the new voltage divider components - all of them are SMDs. The pin numbering on this picture is wrong! This was a temp numbering as if using 14pin socket - this PMT has 12 pins - 10 stage dynodes, Anode and Cathode.

The reworked Dynode Voltage divider, using metal-film, high-voltage SMD resistors and HV ceramic 3kV capacitors. R=2M, 2R=4M for a total of 24M. All resistors are within 1% tolerance and actually better - I purchased extra resistors and used a LCR bridge to select and match 10 resistors as close as possible to the designated value and to each-other. The reason for using 2MOhm resistors in the divider instead of 1M, often used in lab setup PMTs is to minimize the voltage drop as the GS-USB-PRO's HV Power Supply is not incredibly "stiff" as a lab supply so a bit higher impedance helps .

I was able to use the old pads and traces with only one additional small jumper-wire. BNC connector was installed on the cap, sealed and connected via small diameter short coax to the PCB. Unfortunately there is not enough space for an SHV type connector with its longer, insulated center conductor lead. The PMT's Cathode, Mu-metal tube shielding and the detector housing were all grounded together.

The resistors values in the voltage divider are specific for use with GS - the overall impedance is too low if used as a simple scintillation probe with a battery operated Ludlum-type meter for example - in such case 120M divider is expected with R=10M and 2R=20M correspondingly.

The PMT's dynode voltage divider - a pretty standard circuit with the exceptions of the values in my case R is 2M and R1 is 2R or 4M. If this detector is modified for use as a standard scintillation probe (with a survey meter like Ludlum for example), R should be 10M with 2R = 20M - just like on the schematics. Higher impedance is needed in such case for these battery operated meters as their voltage supply is not as "stiff".

One thing I was very pleased to see is that the PMT inside the stainless steel housing had a separate Mu-Metal magnetic shield - both, shield and housing are also internally connected to GND.

My Gamma Spectacular GS-1525 NaI (Tl) detector.

This detector offers better resolution (~6.5% FWHM for Cs-137 / 662 keV) then the Scionix-Holland 38B57 (7.5%) using EPIC 1.5" x 2.5" NaI(Tl) crystal and ADIT PMT but at a much steeper price tag (and it ships from Australia). Same bias voltage - 650V is producing higher level pulse signals. This detector is equipped with SHV connector for both bias voltage and signal.

The beauty of this detector is the encapsulated crystal with an optical window and a separate PMT which allows for service and experimentation with various detector components.

2. Detector Driver - This device is the electrical interface between the Detector and the MCA - it usually contains a High-Voltage Bias power supply for the PMT, coupling/decoupling circuit, an adjustable gain pre-amplifier, ADC and a Sound Card USB chip (in my specific case).

I use Gamma Spectacular GS-USB-PRO (www.gammaspectacular.com) as a Detector Driver and this device is great - I love it and highly recommend it! The unit connects to the USB port and powers the detector as well as it provides the analog (external sound card needed) and digital (built-in sound card in GS) interface to the MCA software. It is a highly configurable, flexible and adjustable device. GS-USB-PRO also provides a very nice stable HV bias supply /w voltmeter and allows for super-easy adjustment of the high-voltage to the PMT - range is 0 to 2000V. I run my detector at 650V - it is a good compromise - lower voltage gives you better linearity but low gain, while high-voltage affects the linearization but gives more gain to pick up weak gamma-emissions (and noise of course). The exact optimal voltage should be determined experimentally because it is tied to the particular condition of the crystal, PMT and voltage divider as well as to the targeted energy range.

All active components of my Gamma Spectroscopy Setup.

The GS-USB-PRO Detector Driver - compact and attractive design. SHV and BNC connectors on the front panel alongside the USB port, analog audio jack and all trimmer adjustments for the high-voltage, pulse shape and volume. On the bottom of the housing there are 2 switches for selecting detector wiring mode and the analog jack mode. The analog jack can serve as an input to connect two units for coincidence measurements. My GS unit is the latest v. 3.2 hardware revision with all modifications to accommodate the Schmitt trigger daughterboard for use with Neutron Detectors.

There is a bright digital voltmeter on the top side of the unit. The trimmer pot on the front is adjustable with a small screwdriver for a range of 0 to 2000V. The voltage readout is absolutely stable and adjustable to 1V resolution.

3. MCA or Multi-Channel Analyzer - this can be either a stand-alone external hardware unit or a software component running on a PC. I use the software version - actually a few of them, running together on my laptop - PRA, Theremino MCA and BecqMoni (all free software btw.). Each application has its own pros and cons but fortunately they can run simultaneously on the same machine and listen to the same detector.

Theremino MCA displaying a typical Thorium-232 spectrum.

PRA displaying the results from a Lu-176 (LYSO Crystals) Gamma-Spectrum Analysis.

If the Detector is the "heart" and the Driver is the "spine", then the MCA is the "brains" of the operation.

What the MCA does is pulse detection and acquisition thru the sound card input, pulse filtering to reject malformed and distorted pulses by evaluating the pulse shape, classifying the pulses by placing them into "bins"/channels based on their energy and building a number of histograms and graphs out of the processed data.

Energy calibration is done using calibration sources, allowing the software to correlate known gamma energies to specific channels. The software will also perform Gaussian detection over the Pulse Height Histogram and detect peaks as potential Regions Of Interest (ROI). A variety of tools such as Detector Resolution Compensation and filtering can be used to process the acquired spectrum.

The software is not extremely complex but requires a good bit of understanding and knowledge in Gamma Spectroscopy and pulse detection and acquisition. Very little is automated and manual evaluation of the spectrum with the help of reference sources is generally needed to identify unknown radio-nucleoids.

4. Interconnects - these are mainly the cables connecting the Detector to the Detector Driver and cable connections for audio and USB to the computer.

GS-USB-PRO supports "Single cable" configuration (which is what I use) where HV bias and signal pulses share the same coax cable) as well as "Dual Cable Mode" - 2 separate lines - one for the PMT HV bias and one for Signal. There are 2 connectors on the front - in a "Single cable mode" only the SHV connector is used. In "Dual Cable mode", configured by a switch, the signal is received over the BNC connector while SHV is used for the PMT bias only.

The critical part is the Signal cable as it should be of a high-quality coaxial type with a fairly low capacitance - best is less than 60pF total (with both connectors installed on). Higher cable capacitance widens the pulses (which normally are very short) and makes their shape "mushy", especially the trailing edge.

The high-voltage cable should be done with a properly shielded coax cable, able to withstand up to 2000V without arcing. For anything above 1000V I would use SHV type connectors (rated at 5000V/5A) - regular BNC are not really meant for high voltages. I installed a female BNC connector on my Detector housing so my single coax is SHV-to-BNC as the detector runs on only 650V and there is not enough space for the extra-long SHV type connector..

Cables are part of the calibration chain - i.e. changing cables WILL require a re-calibration.

5. Detector Shielding - for more details on making the Lead shielding for my detector, please see here!

Portable, field deployment

Lab setup

Part of the inner copper shielding is clearly visible inside the main shielding shells. There are additional, removable copper-tin cylindrical inserts (not pictured here). They are made by rolling a "sandwich" of thick copper foil and real tin (pewter) foil into a tube with wall thickness of 1 mm copper on the inside - 1 mm tin and another 0.5 - 1 mm copper on the outside.

Main detector shield (top) and the "large sample holder" (bottom) mated together - the lead thickness is 22mm around the crystal in the main shield or up to 35-50 mm once the outer sleeve shield and (optional) bricks are installed. In the wooden shield-carrier cradle, the main shield assembly is situated over 3/4" thick base of lead bricks and the outer shield (sleeve) is placed over the assembly on lead raisers.

A stack of bismuth, cadmium, tin and copper disks is lining the bottom of the sample chamber. Pictured here are the tin and copper disks.

This is called "graded shielding". A coper-tin-copper sleeve insert is placed on top of the stack lining the walls of the sample chamber. Similar but longer sleeve insert is located in the upper shell, wrapping around the detector assembly.

A 1/16" thick Bismuth metal disk (on the left) and the Cadmium metal disks as part of the graded shielding for the very bottom of the sample chamber. The goal is to absorb as much as possible of the low energy XRF induced by the gamma rays in the lead shielding.

Outer lead shielding - 12.7 mm of lead thickness.

Nothing beats the looks of an OD Green-colored "canister" resembling device with a bright yellow "Radioactive" sign 😁.

Look inside the detector cavity of the main shield. The little removable copper cup on the bottom is used to hold small high-activity samples or calibration sources or it can be used as a "raiser" (when flipped) to bring the sample closer to the scintillation crystal.

6. Calibration Sources - these are extremely important aids for the proper energy calibration of the instrument. Without accurate calibration the measurements are more or less meaningless.

In theory, any strong radioactive source with a known spectrum and activity can work.

By now, I should have approximately 0.736 uCi of activity left in my Cs-137 Calibration Source made in April 2007.

The 1uCi Eu-152 and Co-60 were freshly made in the beginning of August 2020.

The uncertainty of these sources is generally +/- 20% of the specified activity.

Decay Scheme of Cs-137

The "classic" Cs-137 Gamma-spectrum (peak @661.6 keV) is a good mid-range starting point for the calibration process.

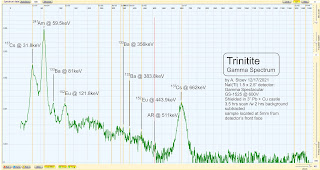

Eu-152 Gamma-spectrum with multiple peaks nicely spaced up to 1408 keV.

There are other energies emitted by Eu-172 but their intensities are just a few percent.

This spectrum was produced with "Sum Quantity" feature in PRA

One of my Lutetium calibration sources - 1 gram of 99.9% pure natural Lutetium sealed in the center of 1" plexiglass disk.

Natural Lutetium contains 2.6% (or 26 milligrams in my sample) of the primordial Lu-176 isotope and it produces two very distinctive gamma photopeaks at 201.83 keV and 306.78 keV and an X-Ray (Kα1 Hf) peak at 55.79 keV. There is another Lu-176, weaker photopeak at 88.34 keV. The natural Lutetium metal has an activity of ~51.6 Bq/gram.

This is a fairly inexpensive calibration source with a price of around $8-10 per gram for the pure rare-earth metal.

Lutetium and Potassium Chloride are excellent "air-travel" calibration sources for when bringing the spectroscopy setup to the field - their radioactivity is extremely weak (Geiger Counters will not even register activity), making them completely safe to carry on-board of an airplane. (attempting to board a plane with a Cs-137 or Co-60 source will likely result in a lot of troubles)

11 hours spectrum scan of Lu-176 from 2 LYSO crystals in a Lead castle (with 9 hours background spectrum subtracted). The plot also shows the Sum peak at around 508.61 keV as well as the 55.79 keV Kα1 Hf-176 X-Ray peak.

The 509keV Sum peak occurs due to the coincidence emissions and detection of the 202kV and 307keV photons.

A Detector Escape peak from the NaI in the detector crystal is usually observed at around 26 keV in the Lu-176 spectrum. This Iodine Escape Peak comes from the K-shell of the Iodine when it interacts with higher energy X-rays and the resultant emission escapes the detector. it is located ~28keV (the binging energy of the K-shell electron of the Iodine) lower than the incident photon causing it - in this case the Hf-176 Ka emission at 55keV.

The escape peak is prominent when the energy is below 200keV - because the difference is so small (only 28keV) for higher energies it falls within the main photopeak and it is usually masked.

Spectrogram-wise, there is no discernible difference between LYSO crystals and metal Lutetium.

LYSO crystals are used in PET detector arrays can be found from a number of sources.

In the absence of a proper strong calibration source, for two-point calibration one can use Potassium (K) which has a small amounts (0.012% of all Potassium) of the primordial isotope K-40 with gamma @ 1.46 MeV (actually, I use about 100g of Potassium Chloride (KCl) as my K-40 source) - such calibration takes fairly long time in order to get a good, measurable peak as the activity is pretty low but while doing this, I can also observe the positron annihilation peak at 511 keV as another point of reference for the calibration. Generally it is good to have a good separation between the 2 peaks and to encompass the targeted energy range. Sources like Eu-152 and Na-22 give very good results for energy calibration.

Normally, my first step is calibration with a Lu-176 source (using Lutetium metal or Lutetium-Yttrium Oxyorthosilicate (LYSO) crystals) with gamma photopeaks at 201.83 keV and 306.78 keV, followed by the "classic" Cs-137 (1.0 uCi) disk source at 661.66 keV and the X-ray peak at 32.19 keV. Next is calibration of the high-energy region using 1uCi of Co-60 disk source at 1.173 MeV and 1.332 MeV. As a final step and confidence check and to fine tune the linearity of the detector, I use 1.0 uCi disk source of Eu-152. Europium-152 produces a number of peaks throughout the spectrum and it is a good way to check the overall calibration accuracy.

Thorium (Thorium Dioxide (ThO2) from a gas mantel) also works well to check the linearity of the detector as it has many peaks from daughter products which are spread throughput the useable gamma spectrum to as high as 2614.5 keV (Tl-208)

Natural Uranium test-source.

1" plexiglass disk with a center hole, housing Autunite crystals. The crystals are completely and safely sealed inside epoxy resin. The resin block all Alpha particles - the Autunite activity was around 6000 CPM but after filling the cavity with epoxy, sealing the mineral, it dropped to 2200 CPM.

This source gives a nice "classic" uranium spectrum with Photopeaks of various daughter products.

Collecting background spectrum for subtraction and energy calibration should be done before AND after main spectrum acquisition to minimize effects of thermal drift and changes in the background - this is especially important for low-activity samples.

Conclusion

I love the portability and compactness of my setup - everything fits in 2 Pelican cases and can be carried in the field. One case contains the detector, driver, interconnects, etc. The other case holds all of the lead shielding components (and weights over 70 Lbs!). The calibration sources are stored inside the shielding for transportation.