There is an additional +9V regulator circuitry (installed on the bottom of the PS support plate) for the Accessory connector - it is used to power transverters, S-parameter test fixture or the RF-IV sensor.

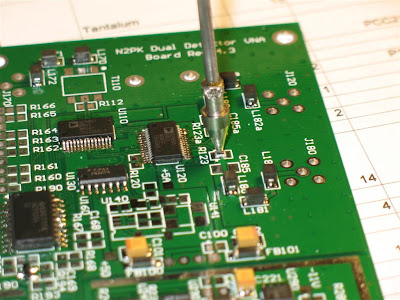

The PCB layout design was done with Cadsoft Eagle. I started with the OM3LZ board as a reference but at the end I changed the layout a bit. These pictures are of my ver. 1.0 board. The final version of the PS PCB is ver. 2.0 and that one is even more compact and with a smaller footprint. Not sure if the 2.0 board will ever see daylight since I am all set with my PS needs for now.

Unfortunately, it wasn't cost-effective to put a silk-screen for the SMD components on the bottom but I don't think it is a big issue.

The resulting surface is smooth, dirt and scratch-resistant and because the printed layer is transparent, the front panel has almost the same brushed aluminum/metallic look as the enclosure. Instead of using transparent print layer, a solid-color stock can be used too, but IMHO it looks "flat" and not as attractive as the natural metallic look. Once the two layers were "sandwiched" and pressed well together, I use scalpel blade to carefully cut out the openings and the excess around the edges.

The finished panels came out very nice and professionally looking - practically "commercial product" grade. I am really happy with the results - I think this will be my method for printing front panels from now on.

While looking for a front panel layout solution, I came across an interesting product - Ink Jet printable laptop skin (sold in Office Max). It is a white, self-adhesive vinyl sheet and I think it could be used for front panel labeling as well but I really wanted to preserve the aluminum finish look so I opted for the see-through label sheets. Another possibility is to use one of the products by http://www.texascraft.com/

The front panel is installed on the enclosure along with the BNC connectors and LO jumpers. I decided to color code the connectors because of their number on the front panel. It will be easier to work with the VNA and keep track of all connections.

The front panel is installed on the enclosure along with the BNC connectors and LO jumpers. I decided to color code the connectors because of their number on the front panel. It will be easier to work with the VNA and keep track of all connections.

Next item on the list is the wiring harness and the power supply board mount.

Update: I made a set of bulkhead (f) BNC to (m) SMA internal RF interconnects, using semi-rigid hand-formable RG-405 coax. I left the old SI316 cables for the LO DDS and replaced only the ones connecting both detector inputs and the DDS RF OUT to the front panel. I did not observe any better detector noise figures.